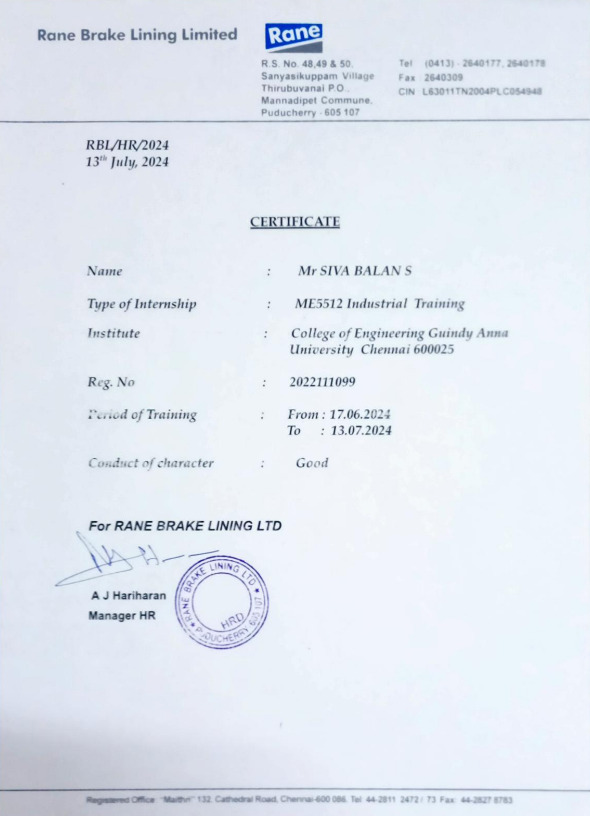

SIVA BALAN S

BE-Mechanical (2022-26) | Brakes Lead @ CEG Motorsports

I am a Mechanical Engineering student at CEG, Anna University, with a strong foundation in design, simulation, and manufacturing. My experience spans supply chain, quality, and new product development through internships and technical projects, supported by skills in CAD/CAE, CFD, data analytics, and AI. I'm a proactive learner and team player, thrive in motorsports, R&D, and innovation-driven environments, aiming to engineer impactful solutions that bridge mechanical systems with digital intelligence.