SAKTHIBALA P

BE-Mechanical (2022-26) | Alumni Relations Lead | Rollcage @ CEG Motorsports

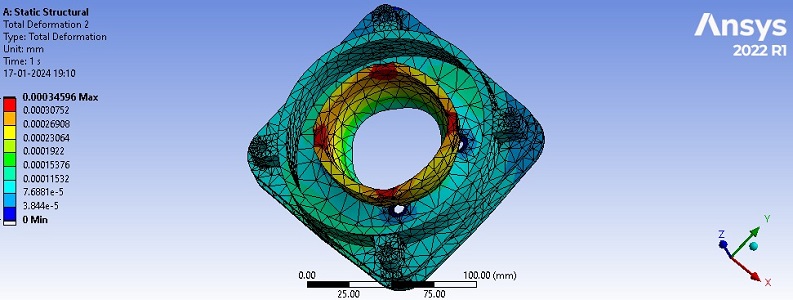

Knowledge oriented and passionate Final Year MECHANICAL ENGINEERING Student. CAD and Astronomy enthusiast. Quick learner with excellent self-learning skills and good academic knowledge. Currently learning FEA to strengthen my Mechanical Design skills.