DEVA ANAND N

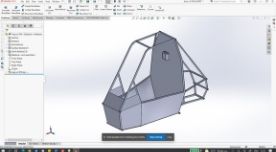

BE-Mechanical (2022-26) | Rollcage Lead @ CEG Motorsports

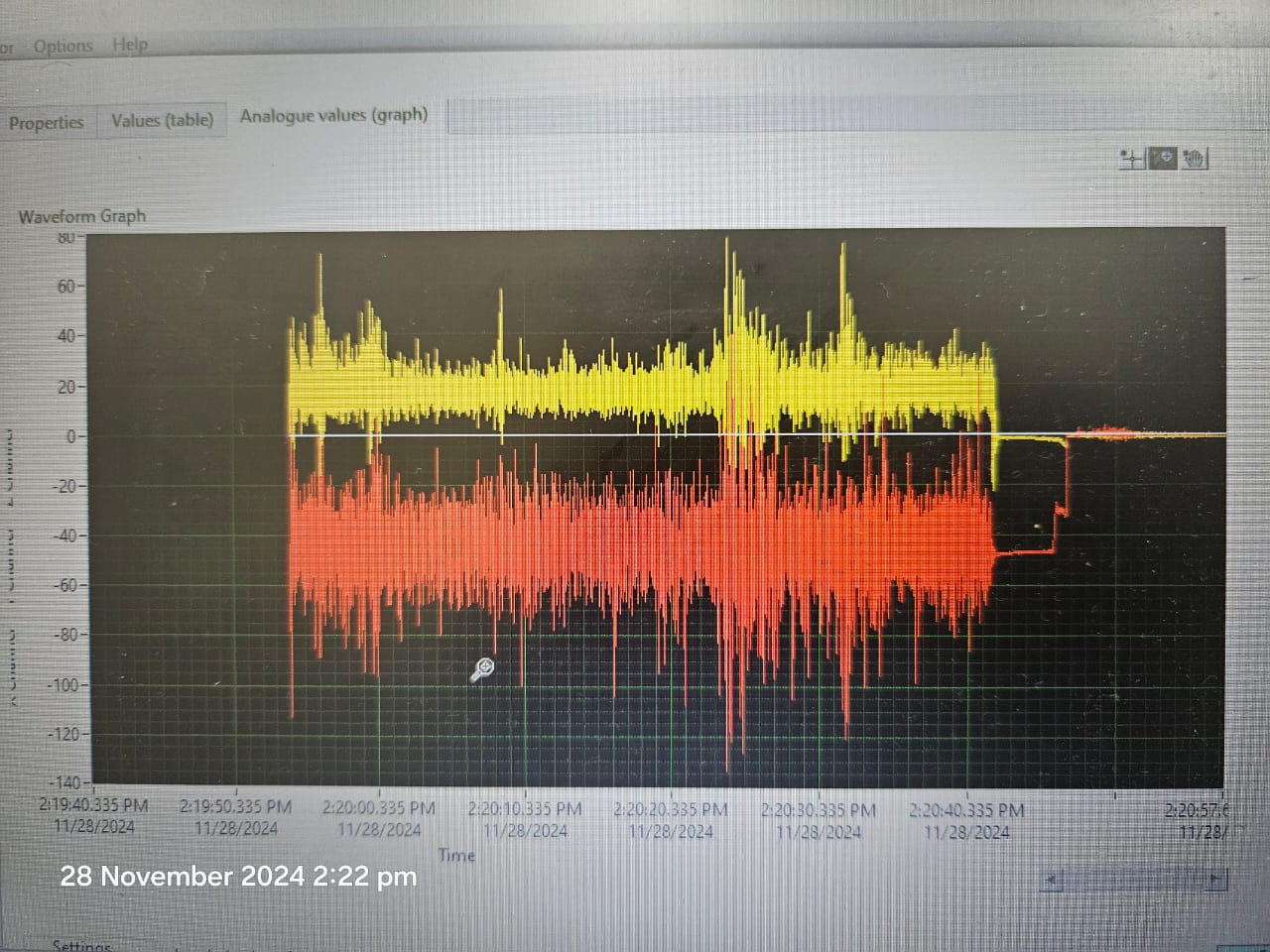

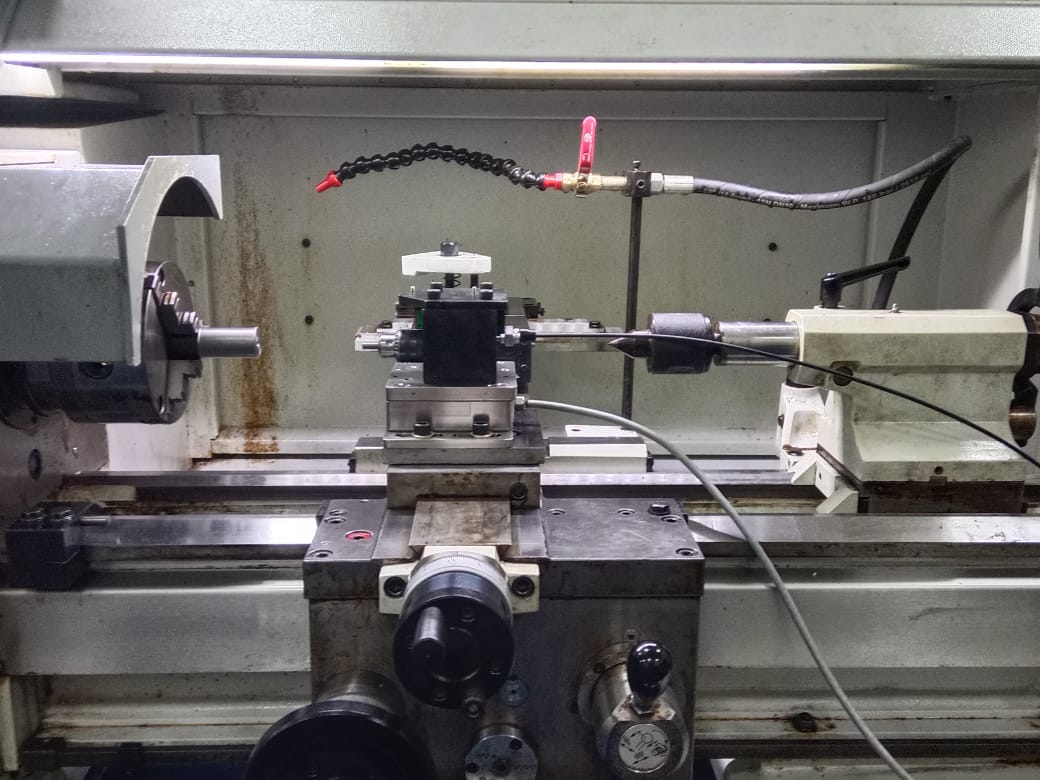

I am a final-year Mechanical Engineering student at the College of Engineering, Guindy, and currently serving as the Rollcage Lead in Team CEG Motorsports. My work focuses on chassis design, simulation and analysis of designs, and assembly integration, applying DFM and DFA principles to improve fabrication efficiency and precision. Alongside technical work, I actively mentor juniors and contribute to documentation and process optimization.Beyond engineering, I am a sportsperson and athlete, with a strong background in basketball, football, and cricket.Sports have shaped my discipline, resilience, and teamwork, qualities I consistently bring into my engineering journey.